Water Chiller Trial with R22, ISCEON®, MO29 and ISCEON®

Test facility:

Coolmation Ltd, Unit 7, Millstream Trading Estate, Ringwood, Hampshire, BH24 3SD

Background and Summary:

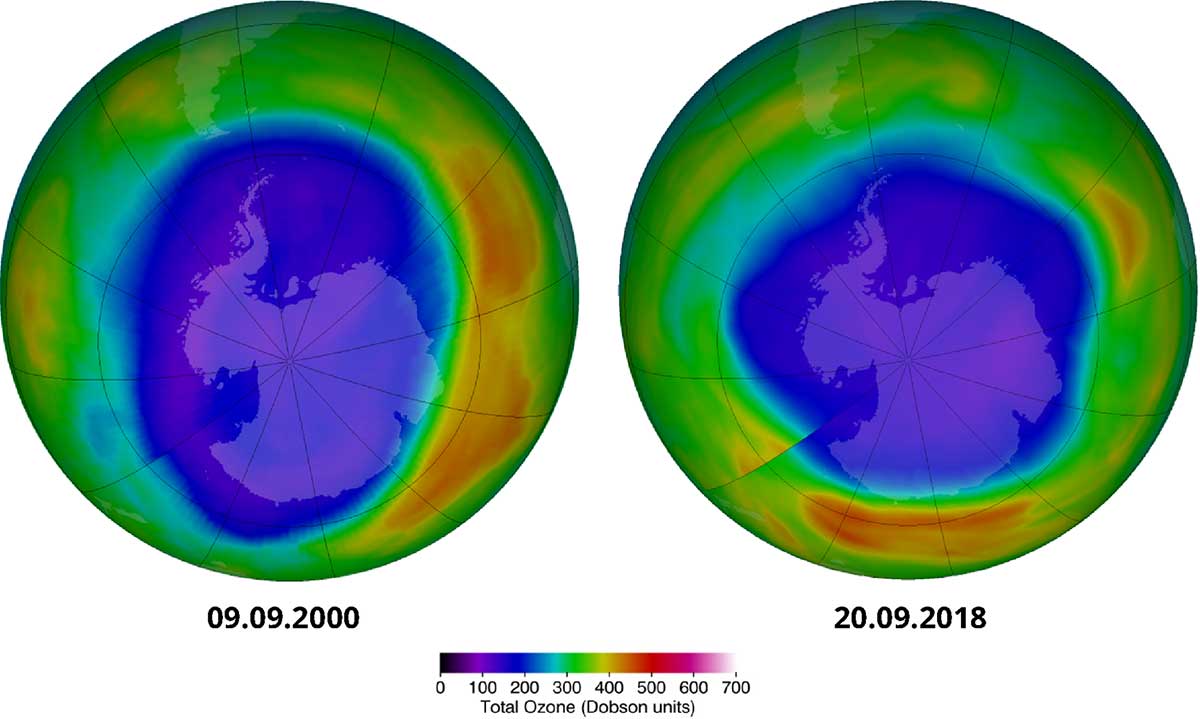

Within the European Union under the EU regulation 2037/2000 the production for consumption in the EU and use of virgin hydrochlorofluorocarbon (HCFC) refrigerants will be banned as of 1st January 2010. This leaves owners of water chillers still operating with HCFC refrigerants with the task of managing the transition from HCFC to an alternative whilst trying to minimise disruption to normal operation of their business.

A number of options exist:

1. Equipment Replacement

- High cost but possible performance improvements over the existing equipment may be obtained.\\

2. Containment and Reliance on availability of Reclaimed HCFC.

- It is very likely that demand for reclaimed material will far exceed supply making this a high risk strategy.

3. Convert to an alternative non-HCFC refrigerant

- Several options exist. A retrofit to Suva®407C would involve time consuming and costly oil flushing procedure to change to a POE based oil.

Another HFC based option is the use of a DuPont™ ISCEON® 9 Series products such as ISCEON® MO99 (R438A). In the majority of direct expansion water chillers, without electronic controls and with simple expansion valves, the ISCEON® 9 Series products would not require a change of oil type and even in those that may require an oil change the time consuming and costly oil flushing procedure required when using Suva®407C can be avoided.

This study shows that using ISCEON® MO99 can have advantages in obtaining best performance in systems where the expansion device is closely sized to the capacity of the system. It should be noted that in many cases where adjustment of the TXV is possible that ISCEON® MO29 is a perfectly adequate replacement for R22. However, it has been found in some water chiller applications that in order to get best performance from ISCEON® MO29 it is necessary to change the orifice or even complete expansion valve to a larger capacity type. Use of ISCEON® MO99 avoids this and therefore provides a solution requiring the absolute minimum of system changes.

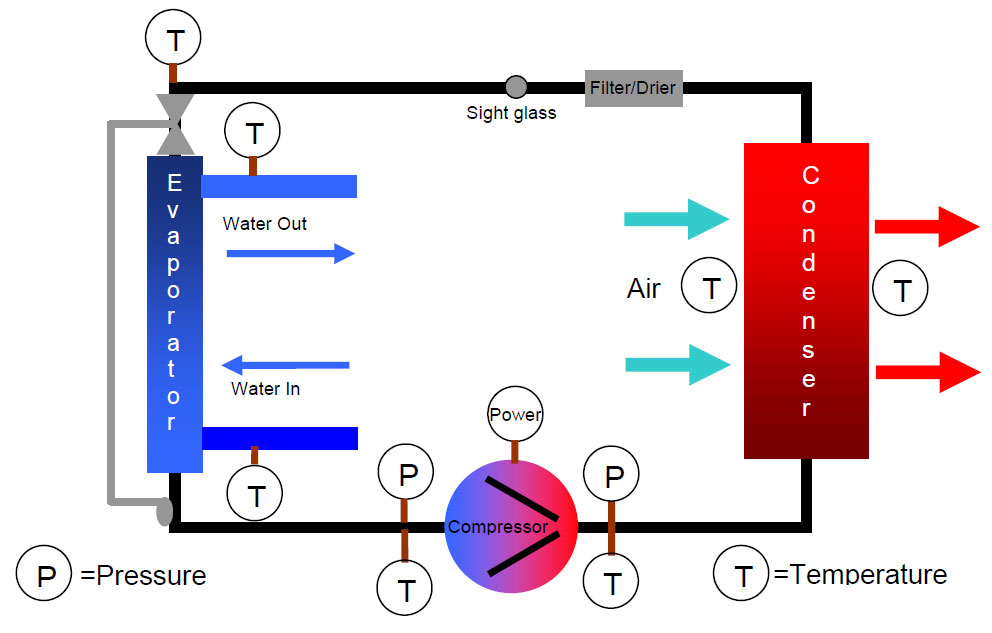

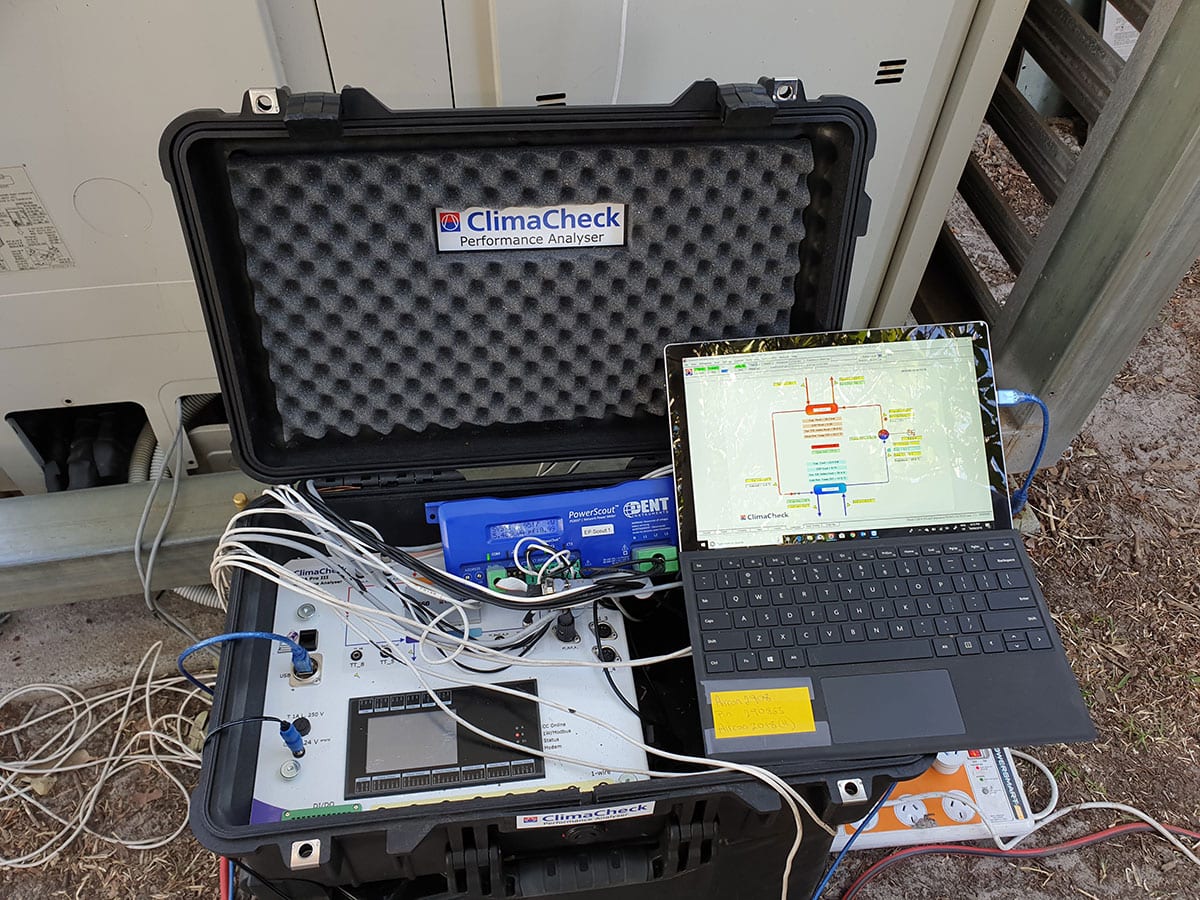

The system was monitored using a Climacheck Performance Analyser. The measurement points are shown below in the system layout diagram.

Test Equipment and Method:

The system chosen for the testing was an Airedale water chiller with a nominal cooling capacity of 80 kW with R22. The system consisted of two independent refrigerant circuits (40kW each) with a common water source through two plate heat exchangers. It was decided to retrofit and monitor only one of the two circuits as it was only possible to monitor one system and the maximum available load on the water supply was approximately 40 kW.

Each circuit used a Maneurop MT160 hermetic reciprocating compressor using the Maneurop 160P mineral based lubricant, Sporlan SVE-10-GA thermostatic expansion valve, filter drier, plate heat exchanger evaporator and a forced air fin and tube condenser coil.

The test procedure would be done in a way that would resemble a real retrofit situation and no system adjustments were made during the retrofits. This would then simulate a system where there was no further adjustment possible on the TXV. Initially the R22 was monitored then the system was changed to ISCEON® MO29 and finally ISCEON® MO99.

For each test the source water was heated to approximately 30ºC and then the chiller was switched on. The source water was allowed to cool to 20ºC, held for a period at this temperature and then allowed to cool to 15ºC and held once more.

The R22 was recovered and the system evacuated to at least 500 mbar before recharging. 10.3 kg of ISCEON® MO29 and ISCEON® MO99 were used in the subsequent trials.

Experimental Results and Data Analysis:

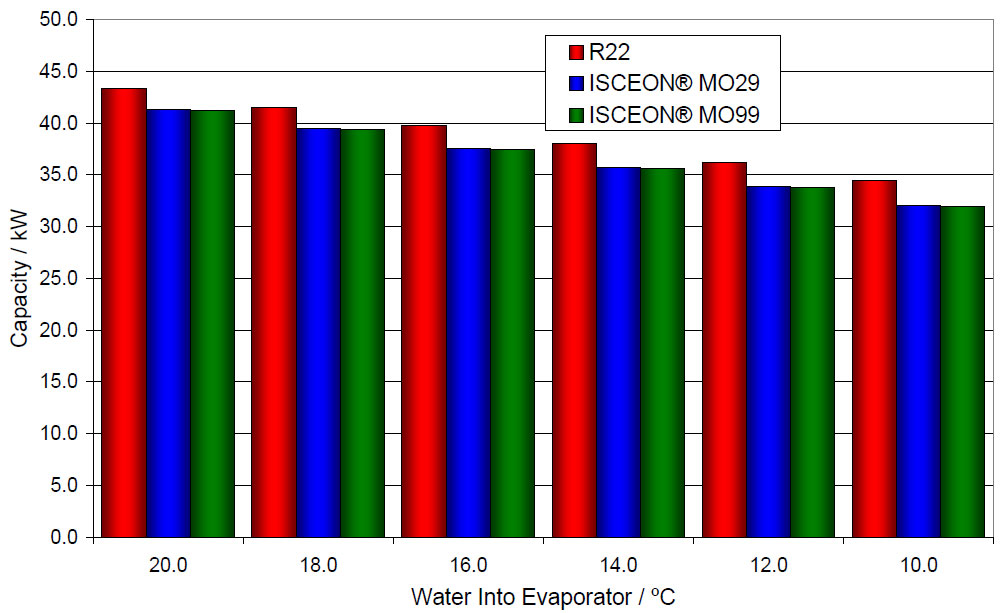

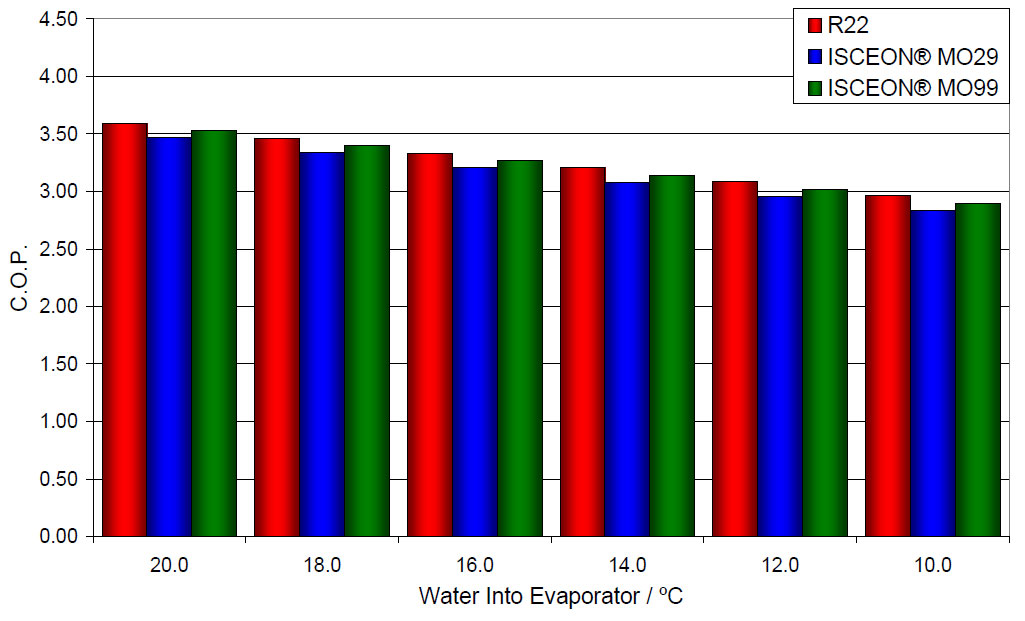

The data points were logged at 5 second intervals. From the data gathered it was possible to curve fit and calculate sets of operating conditions at water inlet temperatures between 20ºC and 10ºC at 2 K intervals.

Using this data it was possible to calculate the expected theoretical performance of ISCEON® MO29 and ISCEON® MO99 from the R22 data measurements. The theoretical performance is shown in the accompanying graphs.

Experimental Results and Data Analysis:

The data points were logged at 5 second intervals. From the data gathered it was possible to curve fit and calculate sets of operating conditions at water inlet temperatures between 20ºC and 10ºC at 2 K intervals.

Using this data it was possible to calculate the expected theoretical performance of ISCEON® MO29 and ISCEON® MO99 from the R22 data measurements. The theoretical performance is shown in the graphs below.

The theoretical cooling capacity results for ISCEON® MO29 and ISCEON® MO99 are near identical to each other and ranging from 5% lower than R22 at 20ºC water inlet temperature to 7% lower than R22 at 10ºC water inlet temperature.

The Theoretical C.O.P. results show ISCEON® MO29 has a lower C.O.P. than R22 ranging from 3-5% (20ºC to 10ºC Water inlet temperature). ISCEON® MO99 also shows a lower theoretical C.O.P. than R22 of between 2% and 3%.

Based on the theoretical results there is practically no difference between the performance of ISCEON® MO29 and ISCEON® MO99 with a performance similar to that of R22.

It can clearly be seen from the data that there is a significant difference between the theoretical and actual performance with ISCEON® MO29. There is virtually no difference in the performance between the theoretical and actual values for ISCEON® MO99.

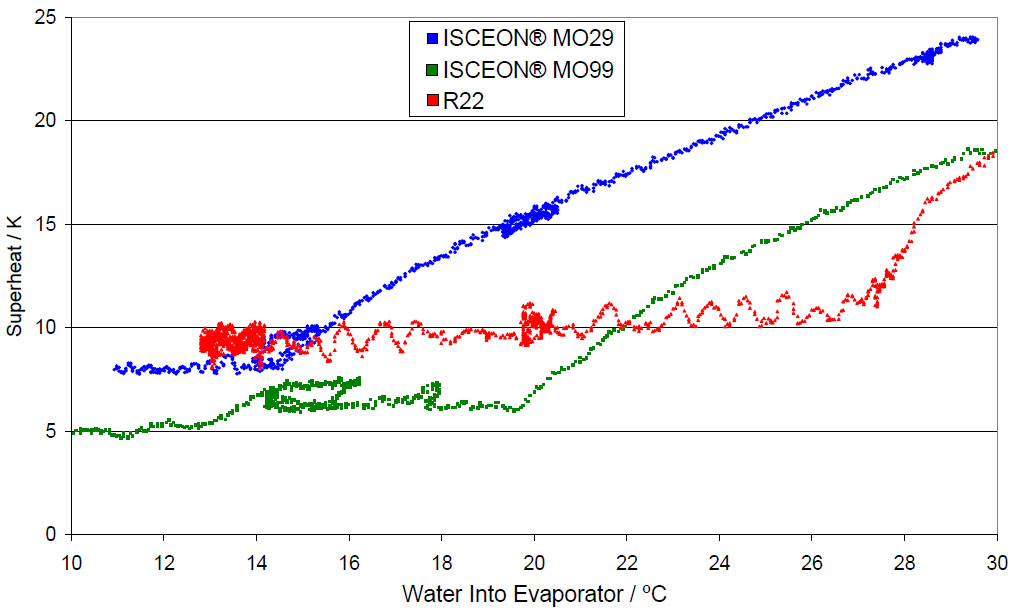

The explanations for the observed differences with ISCEON® MO29 are mainly due to expansion valve sizing. The expansion valve sizing issue can be clearly seen by comparing the evaporator superheat values as shown in the above diagram.

It can be easily seen when the expansion valve control region is reached as the superheat line flattens with a small oscillation around the mean point. When operating with R22 the expansion valve control region is reached very quickly when the evaporator water inlet temperature is approximately 27ºC. With ISCEON® MO99 the control region is reached at a water inlet temperature of 20ºC, and with ISCEON® MO29 at an inlet temperature of 15ºC.

In practice this means the system cooling capacity will be restricted before the expansion valve control region is reached and this can clearly be seen where ISCEON® MO29 is predicted to be 6% -10 % higher than the actual system measurement at inlet water temperatures of 16ºC to 20ºC.

In contrast to the ISCEON® MO29 results the ISCEON® MO99 results show excellent agreement with the theoretical values on the cooling capacity with a slightly higher C.O.P. measured at water inlet temperatures below 16ºC.

It should be noted that systems that operate with low evaporator superheat with R22 may be at risk if retrofitted to ISCEON® products unless the expansion valve superheat setting is adjusted to compensate for the observed superheat reduction.

Conclusions:

The theoretical analysis of this water chiller using ISCEON® MO29 and ISCEON® MO99 based on the measured data with R22 indicated that both products would give a 5-7% reduction in cooling capacity and a reduction in system C.O.P. of 3-5% using ISCEON® MO29 and 2-3% using ISCEON® MO99.

However the practical measurements after retrofitting the system without any system modifications or adjustments showed a significant difference between the performance of ISCEON® MO29 and ISCEON® MO99. This simulates the situation where the system TXV has no further adjustment.

The cooling capacity after retrofit to ISCEON® MO29 relative to R22 was lower than the predicted value at between 13% lower (at 20ºC water inlet temperature) and 8% lower (at 10ºC water inlet temperature) with a C.O.P. 9-6% lower (20ºC-10ºC water inlet temperature). In addition the ISCEON® MO29 was operating outside the expansion valve control region until the water inlet temperature had dropped to ~15ºC.

The cooling capacity after retrofit to ISCEON® MO99 relative to R22 was closer to the predicted value at between 4% lower (at 20ºC water inlet temperature) and 3% lower (at 10ºC water inlet temperature) with a C.O.P. 5-0% lower (20ºC-10ºC water inlet temperature). When using ISCEON® MO99 the expansion valve control region was reached much quicker than with ISCEON® MO29 at a water inlet temperature of ~20ºC.

The results of these trials have clearly shown that ISCEON® MO99 has a significant benefit for cooling capacity, energy efficiency and system control over ISCEON® MO29 in water chiller applications where the expansion valve is closely sized to system capacity.

DISCLAIMER

The information provided herein is believed to be accurate, but is not warranted nor is it intended to be used without independent verification. Because it is provided gratis, the reader assumes sole responsibility for any results obtained in reliance on this information. Statements or suggestions concerning possible use of our products are made without representation or warranty that any such use is free of patent infringement, and are not recommendations to infringe any patent. The user should not assume that all safety measures are indicated, or that other measures may not be required.